交通類別

Projects

諾丁漢火車站

Nottingham Train Station has benefitted from a £150 million investment to position Nottingham as the transport hub for the East Midlands. The multi-million pound project has succeeded in improving reliability, reducing train delays, and has created the capacity to cope with the increasing number of passengers coming through the station every day.

Significant changes made to the station include; a modernised station entrance, new ticket office, revamped first class lounge, a newly-installed platform and canopy to help provide flexibility around the station and deliver more reliable train services, as well as a full refit of the surrounding cafés and shops.

The appointed sub-contractor on the refit of all station floors and platforms was DMC Contracts Ltd, a provider of multi-disciplinary services, combining design, installation, product integration and interface management for projects across a variety of market sectors.

Conor McCann, Director of DMC Contracts based in Essex, said “This project was particularly challenging as we were required to manage a complete refurbishment of the existing station whilst also ensuring it remained live and functional throughout the build. It was important that the project was completed in as short a time frame as possible, but the schedule was extremely demanding and we needed products to suit. This is where I specified that ARDEX be bought in; I knew the brand had fast-track solutions that would help us to get the project completed on time”

Paul Forrester, Business Development Manager at ARDEX UK explained “We have previously worked with DMC Contracts on a number of high profile Network Rail and London Underground projects, including Embankment Station, Merseyside and Kings Cross Station. Their team is very familiar with ARDEX products, and in this particular instance it was the benefits of our rapid drying screeds and tile adhesives that was urgently needed to complete the project on time.

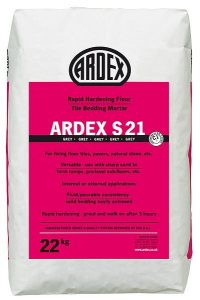

ARDEX A 38 Ultra Rapid Drying Cement for Screeds can be tiled just 4 hours after application, regardless of thickness, and ARDEX S 21 Rapid Hardening Floor Tile Bedding Mortar can be walked on and grouted after 3 hours.

Conor explained “The main benefit we experienced using ARDEX products was the rapid curing time and strength of the finished product. This meant that work could continue at a much faster rate as tiles could be laid and surfaces walked on only a short time after work was completed on it. This helped to ensure the project was successful, and the quality of the products meant they required zero maintenance after application and are built to withstand and perform under the demanding conditions of a busy train station.”

Products used for this project

-

ARDEX A 38 (期貨/進口品)

超快乾整平砂漿

- 3小時後可步行

- 4小時後可固定水泥及天然石材

-

ARDEX DPM 1 C

One Coat Surface Damp Proof Membrane

- Protects the floorcovering from residual construction moisture and ground water vapour

- Can be used where a structural DPM is not present or is ineffective

-

ARDEX-FLEX FL

曲折型速型瓷磚填縫劑

- 施作後90分鐘可步行

- 35色可供選擇

-

ARDITEX NA

超快乾乳膠底層自平材

- 無需底塗,絕佳的黏著性就能與幾乎所有材質對接

- 不反潮

-

ARDEX S 21

Rapid Hardening Floor Tile Bedding Mortar

- Ideal for solid bed fixing large format tiles and natural stone

- Walk on and grout tiles after 3 hours

More projects in 交通類別

-

倫敦Heathrow國際機場第一航廈

ARDEX’s advanced flooring products assured a perfect installation was completed on schedule

-

國王十字車站售票大廳

An 85mm deep screed walkable faster than the journey time from Platform 6 to Newcastle!

-

諾丁漢火車站

ARDEX provided a complete system of products as part of a £150m investment plan

-

Glasgow 國際機場大翻新

One of the most significant and comprehensive upgrades to Glasgow Airport since it opened in 1966

-

倫敦Piccadilly地鐵車站

500,000 tiles were fixed in 1984 using ARDEX products, and remain fully bonded today